by Brennan Stoelb, Animal Care Specialist, Wolf Haven International

Sequra, a 14-year old female wolfdog enjoys her loaf.

Lakota, a male wolf, takes a leisurely approach to dining.

It has been almost two years since I last wrote about wolf “loaf.” As you may or may not recall, Wolf Haven is part of a program called Sustainable Solutions. Their goal is to reduce food waste caused by unsold products. By connecting animal facilities like Wolf Haven and food stores, meat that would normally be disposed of in a landfill or a rendering plant can be utilized. Disposing of unsold food items costs the stores money. Animal rescues often have a never-ending need for meat. Through Sustainable Solutions, both party’s needs are met, while cost and waste can be reduced.

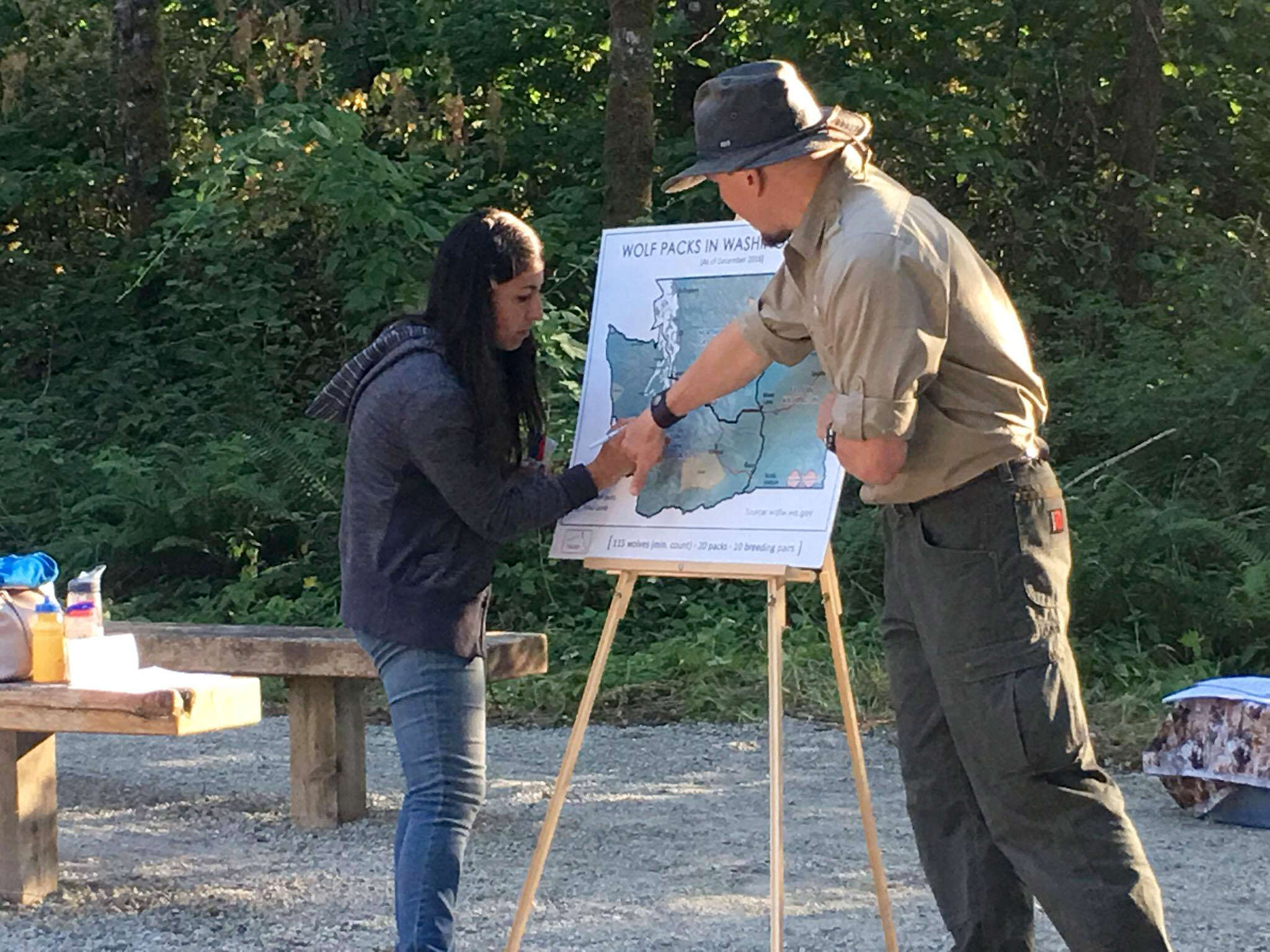

Wolf Haven volunteer Marinka helps Brennan sort the meat & makes loaves

Every Friday, two animal care staff hop into our trusty white cargo van, head to a popular food store and collect roughly 800-900 lbs. of scrap meat. This meat ranges from unusable items such as bacon, ham, and other processed meats, to usable steak, chicken, and beef. We do not feed processed meats due to the high fat and sodium content; on average, I would say that half of the meat is usable.

After we sort through the meat, we need to feed it to the wolves efficiently. Originally we made loaf in disposable, paper food trays (like you get French fries in at a fair). We would pack the bottom with ground beef, lay on a piece of chicken, and top it off with a steak. Once formed, each loaf was put in the freezer. This yielded a roughly 2 lb. loaf that was easy to feed and utilized as much of the good meat as possible. When we were ready to feed the loaf, we pulled it from the freezer to defrost and then had to remove the food trays, often stuck to the meat. That was Wolf Loaf; we now enter Wolf Loaf 2.0!

Brennan loads a tray of individual loaves

In mid-summer, I began looking at ways to store the loaf better in our small freezer. Meat that we purchase plus the often-present deer carcasses used for feeding take up a lot of space. Add a couple of 50-gallon tubs for loaves, and you’re nearly out of room. A lot of vertical space wasn’t utilized, so a shelf made sense. We purchased two bread carts for storing the loaf, as well as their corresponding metal trays.

We also wanted to get away from using paper food trays. We didn’t like the waste they produced, as well as time (maybe 10 minutes total) lost removing them from the loaf. My previous experience at another wolf facility led us to start using bread pans. We could pack the ground beef, chicken, and steak into the bread pan and turn it over on a tray. We then put the loaf tray on the rack and freeze them. Step two complete!

Feeding scrap beef provided some challenges. When tossing the scrap meat over the fence, pieces inevitably got stuck in the fence, which the person feeding had to dislodge. As good as our throwing arms may be, pieces of meat also got stuck in branches and taken away by ravens. Reducing waste in the form of lost meat was another huge factor.

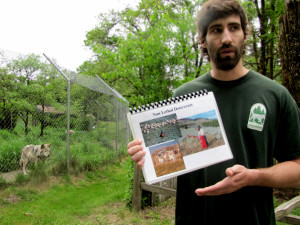

The art of making loaves

By combining the donated meat and scrap beef, we can make bigger loaves and go from a 2 lb. loaf to a 4 lb. loaf easily. Feeding 4 lb. loaves twice a week equals 8 lbs. Since we had been feeding 4 lbs. of scrap beef and 2 lb. loaf twice a week, each wolf still gets the same amount of meat.

With all the pieces in place, we are now on our fifth week of feeding the new loaves. This week will be our first time not feeding scrap beef. With this new system, we hope to reduce waste and become more efficient, a plus for humans and wolves!

Partially thawed loaves are ready to give to the wolves